JK UVC Germicidal Lamp Science

Ultraviolet / Virus Inactivation

Viruses, bacteria, mold, spores and other harmful microbes exist in air,on surface,and in water which serve as a source for infections and healthproblems.JK's UVC Germicidal lamp system is capable of killing 99.99%of these micro-organisms effectively and energy-efficiently with noresidual and contaminants while meeting various national andinternational regulating standards.

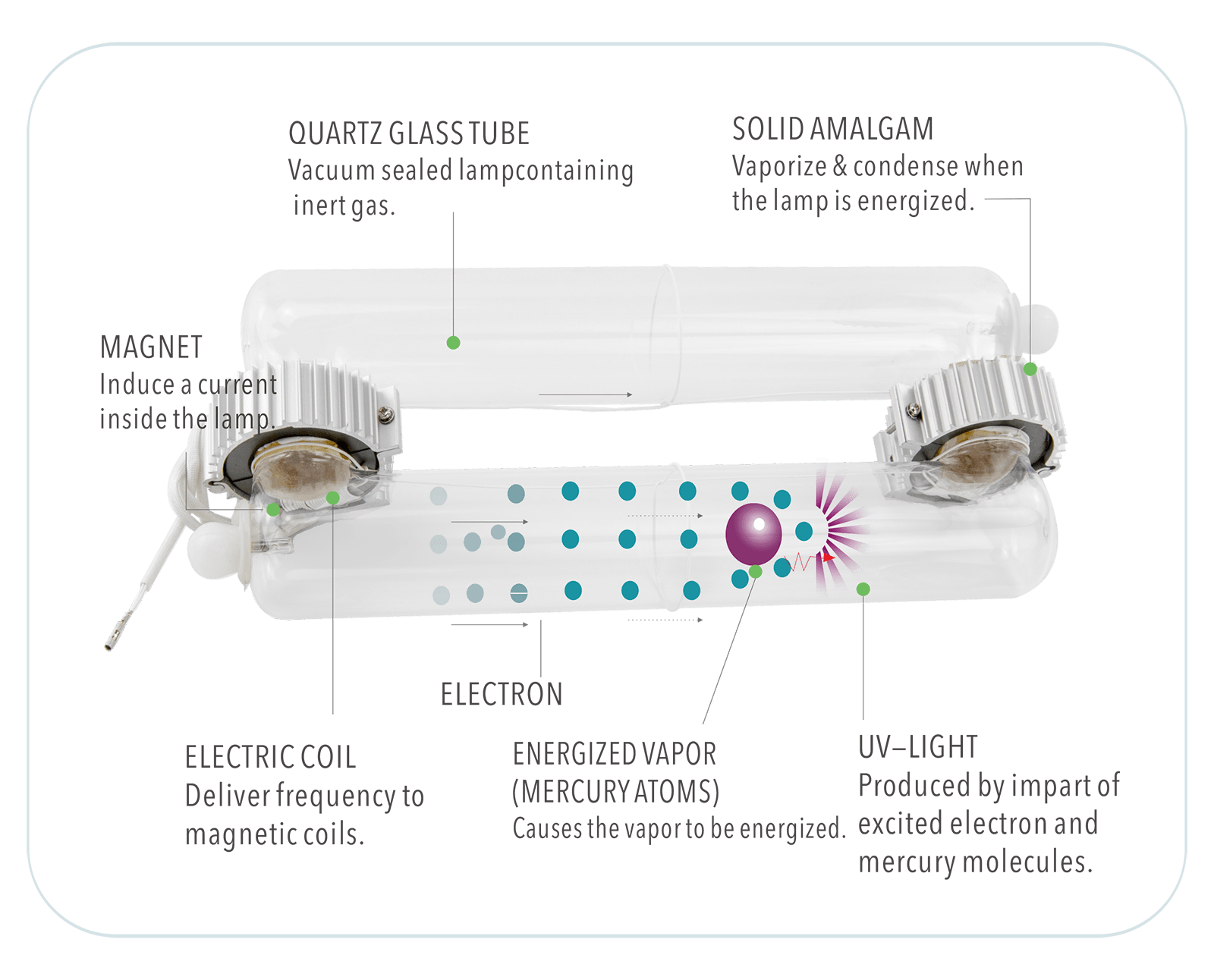

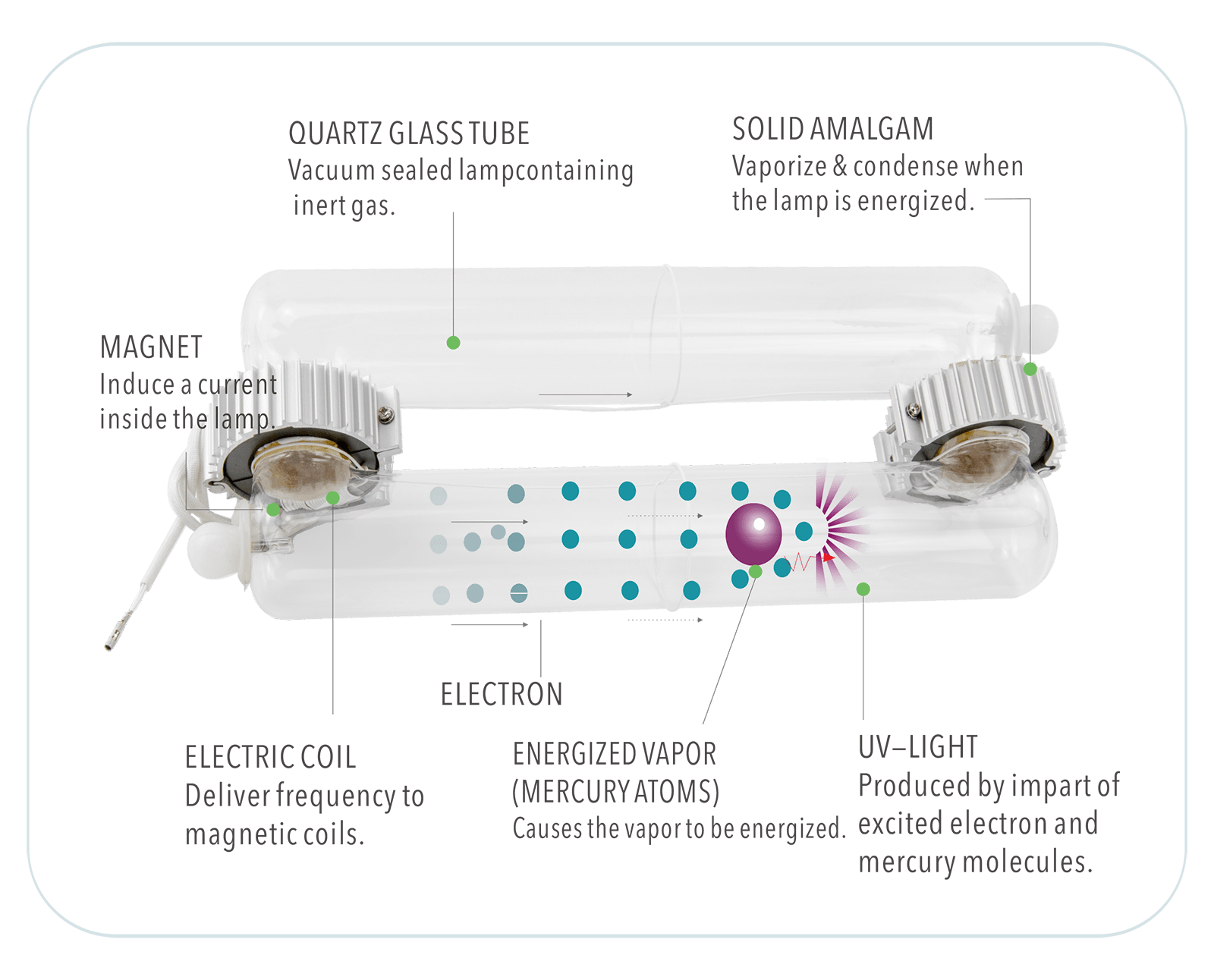

Working Principle & Innovations

Induction lamps are basically fluorescent lamps with electromagnetics wrapped around a part of the tube. In external inductor lamp, high frequency energy, from the ballast, is sent through wires, which are wrapped in a coil around the ferrite inductor on the outside of the glass tube, creating a powerful magnet.

The induction coil produces a very strong magnetic field which travels through the glass and excites the mercury atoms in the interior. The mercury atoms are provided by the amalgam (a solid form of mercury). The excited mercury atoms emit UV light of 253.7 from the quartz lamp envelope.

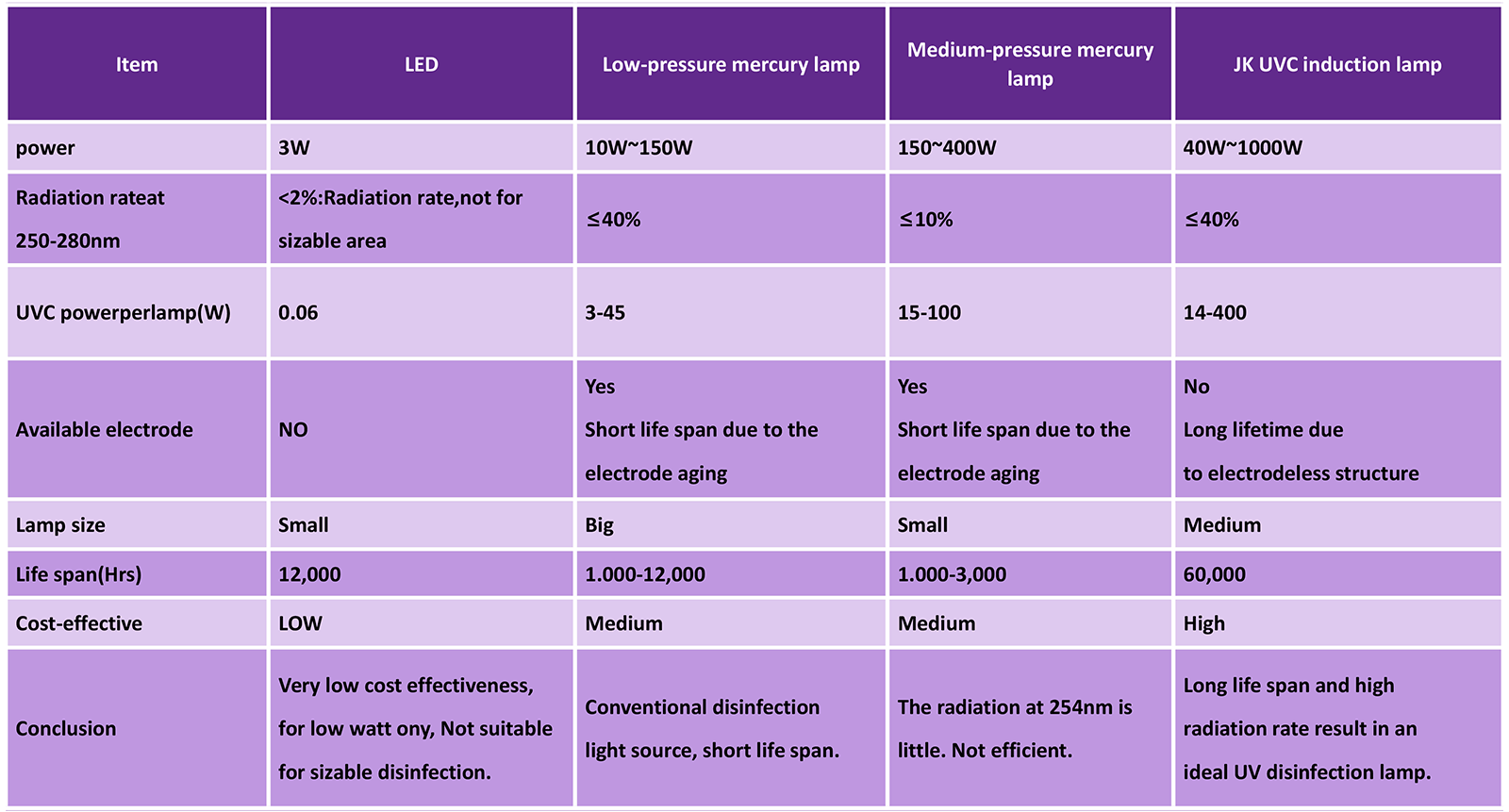

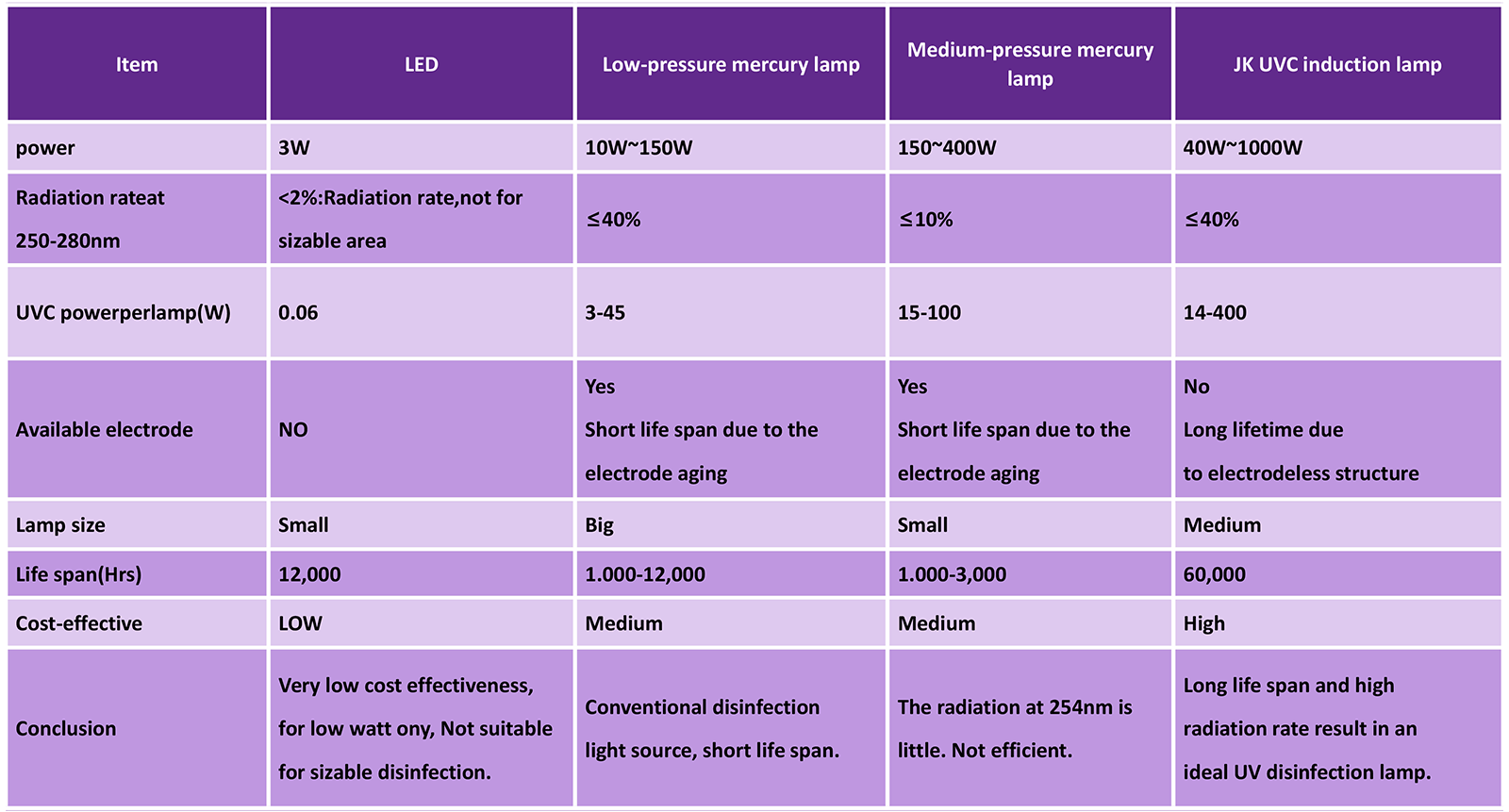

What are advantages of UV electrodeless induction lamp technology?

• Proved and matured technology: The technology exists more than a hundred years and JK has installed millions of visible induction lights globally with high quality and low failure rate.

• Long lifetime: The induction technology uses the frequency induction to drive the lamp. There is no electrode to kill the lamp as conventional fluorescent lamp. The lifetime is 100,000 hours and the standard warranty period is 60,000 hours or 5 years.

• No re-lamping in 5 years virtually eliminates the costly down time and maintenance

• Low light depreciation: 70% or higher light maintenance rate at 60,000 hours

• No negative in lifetime of lamp even with frequent power on & off

• Instant on/off and instant hot restrike eliminate warm-up

• Instant strike regardless of long shelf time and darkness

• Extensive suitable ambient temperature range: 0-50℃ (32-122℉)

• Inherently emitting UV light: The excited mercury atoms emit UV light.

• No liquid mercury: The technology uses mercury amalgam which is easy to manage, collect and dispose.

• High UV penetration rate: The pure quartz lamp envelope is used.

• Strong UV radiation intensity

• Pure, high intensity and uniform 253.7 nm radiation: With optional material of lamp envelope, the wavelength of 185 nm will be radiated as per application.

• High UV conversion efficiency: UV radiation power is 35 to 40% of total output power depending on models.

• Optional ozonic and ozone-free lamp

• Direct submersion in water and direct contact with water without additional quartz protective sleeve for high radiation and disinfection efficiency when in use in water

• Available power as high as 800W eliminates the need for invasive rows of multiple cables, ballasts, controls and power cabinets.

• Low ballast loss: The power factor of ballast is over 99% and it is an electronic ballast.

• Good for tough area where the power supply fluctuates significantly or dirty power occurs

• Stable output: Output power fluctuates within 3% when supply voltage varies in 10%.

• Sturdy and durable ballast design with military graded electronic components and high quality extruded aluminum housing for maintenance free and low operation cost.

• Optional dimming with 0-10V function for controller with display screen, laptop or mobile phone APP for energy efficiency, smart control and remote control

• No EMC issue: Compliance of CE Standard 55014

• Optional supply voltage: 120~277Vac for American market or 220~240Vac for Asian and European market, 50/60Hz

Comparison between uvc induction germicidal and chemical germicidal

What is UV-C Dosage?

The combination of UV-C radiation intensity, duration, and exposure time is used to calculate the actual dosage delivered. Dosage is expressed as micro joules per centimeter squared (mJ/cm²).

Each type of microorganism encountered will require different dosage amounts to sufficiently damage the pathogen.

Applications

The UV-C germicidal lamp systems or devices can be used in the disinfection of viruses, bacteria, spores, fungies, yeasts and other micro-organisms and pathogens in air, on surface and in water.

It can be used in the following indoor areas.

• HAVC systems (commercial, industrial, healthcare, and residential)

• The UV-C germicidal lamp systems or devices can be used in the disinfection of viruses, bacteria, spores, fungies, yeasts and • other micro-organisms and pathogens in air, on surface and in water.

• It can be used in the following indoor areas.

• HAVC systems (commercial, industrial, healthcare, and residential)

• Schools, restaurants, airports and hotels

• Medical:Laboratories, hospitals, and clinics,Pathology labs, kidney dialysis

• Pharmaceutical production

• Food processing (processing, warehousing, handling, production dept., salad bars, buffets, bakeries, restaurants), meat, • poultry, dairy -agriculture plants

• Bottling facilities:Soft & fruit drinks, and juices,Brewery & winery

• Agriculture (animal husbandry)

Industries:

• Cosmetics and electronic production

• Metal & mechanic plants

• Biotech industry (research labs, biotech labs, equipment sterilization)

• Public & private ground [buses, vehicles, trains, sub-ways, trucks] and air [aircraft cabins, airports] transportation disinfection

• Clean rooms

• Public toilets

• Printing

• Personal UV-C disinfection units

• Banks money disinfection

• Lake & pond reclamation Water

• Water treatment plants

• Water plants purification

• Water wells & water cisterns

• Households under sink installations

• Ice making machines

• Water vending machines

• Laundry water

• Aquarium, hatcheries, and nurseries

• Swimming pools & hot tubs

• Farms, ranches & trailer parks

• Boats & recreational vehicles

Safety Tips and Precautions

• Never use UV germicidal device as for lighting purpose.

• At NO time should UVC products for UNOCCUPIED Spaces be permitted to operate with humans, animals, or • plants present in the operation area. Must use multiple safety systems such as PIR, microwave detector, timing • switch and time delay switch to prevent accidental UVC exposure.

• Limit access to areas where UV sources are used.

• Post warning signs at the entrance to labs, halls or other work areas using UV sources.

• Wear protective eyewear and gloves.

• Cover arms and neck and limit exposure time.

• Never look directly at the beam.

• Use a manual or electronic shutter to close the beam when the source is not in use.

• Use enclosed beam paths where possible.

• Exposure to UV radiation, even for short periods of time, can be hazardous to skin and eyes.

• Never place glass before UVC light source as it impairs the UV penetration.

• Unplug and disconnect the power and the lamp shall be extinguished before any service and access. Do not service when the lamp is still hot. Wait until it cools down.

• Do not try to service the lamp system. Consult a manufacturer representative for service.

• Use cloth to collect the broken lamp and dispose it environmentally as per local regulation.

• UVC light source always generates certain amount of ozone. Keep the room or enclosure well ventilated. Wear respiratory masks when entering concentrated rooms during and after UVC disinfection when ventilation is not enough.

• The surface disinfection requires a clean and flat surface with no texture, obstacles and shadow.

• The surface disinfection is directional, so multiple and full-around UVC disinfection are recommended for complete sterilization.

• Ultraviolet (UV) light imposes degrading effects on different types of materials and surfaces such as rubber, plastic, coating, painting, ceramics, leather and glass, etc.

• At times when exposure to the light is unavoidable (for example, when using UV hand lamps to disinfect a surface or object), use protective eyewear such as glasses, covered visors or full face masks. Cover as much of the hands, arms, legs and neck as possible. Avoid touching a disinfection lamp that is on.

• Correct installation ensures proper disinfection. Keep children away from the UVGI. Multiple UVGIs may be needed for right dosage. Right duration and distribution angles are also important. Humidity may be a factor of efficient disinfection.

• Always follow safety precautions published by the manufacturer, local and state authorities.

Min ICP 2022003414-1

Min ICP 2022003414-1