Product advantages

Ultraviolet (UV) water disinfection technology is a proven and sustainable water treatment method as the UV light kills up to 99.9% of viruses, mold, sports and bacteria with right dosage.

JK’s UV induction lamp emits strong UV light at wavelength of 254nm with ultra long life span.

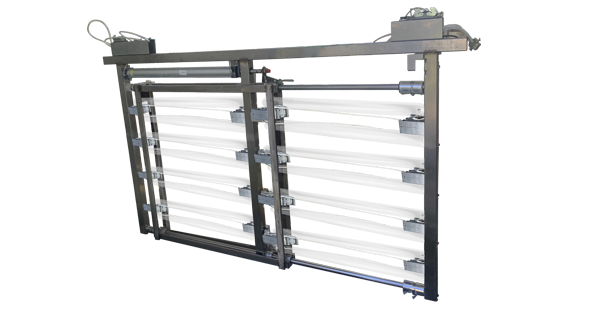

JK’s UV water disinfection system is a modular design consisting of UV induction germicidal lamp module,

electronic ballast module, auto cleaning module, water level control module and control cubicle module for open channel water disinfection. Each lamp module is made of stainless bracket. The control cubicle is integrated with

operation data collection, lamp operation status indication, timing control, surge protection system, dimming

control, etc. Due to the modular design, the lamp system can be single lamp or multi lamp combination for easy

maintenance, operation and installation. The induction lamp is engineered to submerge in water directly without a protective sleeve, which blocks UV penetration resulting in less efficiency as the traditional UV lamp.

Modular design with single or multiple lamp arrangement resulting in easy installation and maintenance as well as simple retrofit of existing system.

Low operation fee: UV induction lamp is featured with life span as long as 60,000 hours. The system requires the built-in auto cleaning of lamp only. No chemical disinfectant is needed.

High UV exposure: The UV induction lamp is submersible in water without a protective sleeve which blocks UV light significantly. Water is exposed to the UV energy directly with UV induction lamp.

More affordable: Optional maximum power of individual lamp up to 700W means less lamps, but stronger UV energy, higher penetration and higher efficiency.

High adaptability: Good for ambient temperature of 0 to 50 ℃.

Chemical free disinfection, no residual or by- product and improvement of taste.

Product features

Product Design: Adopting modular design, each infinite ultraviolet disinfection module is made of corrosion-resistant stainless steel material, and the connecting wires are made of PTFE wires. The quartz lamp tube and wires can be safely used in sewage and ultraviolet radiation.

Automatic cleaning system: Adopting automatic mechanical cleaning method, ensuring that the cleaned lamp tubes and modules work normally throughout the entire cleaning process.

Light source: Equipped with our company's 200-700W high-quality, high transmittance dual quartz electrodeless ultraviolet disinfection lamp, it has the characteristics of ultra long lifespan, high ultraviolet radiation, economic and environmental protection, safety and intelligence. Multiple sealing and waterproof treatment, the double quartz electrodeless lamp tube is tightly installed, and it will not fall off due to friction during automatic cleaning.

Electrical appliances: The electronic ballast is equipped with a quick connector. When repairing the ballast, there is no need to lift the module out of the water surface, which will not interrupt the disinfection process.

Fault alarm system: Power interruption alarm for UV sterilization system. The working condition of each UV lamp is independently displayed. A few individual lamp tube problems will trigger lamp tube malfunction alarms; The alarm can display the position of the problematic light tube.

Heat dissipation method: The small and medium-sized control box adopts a long-life, energy-saving and efficient axial flow fan to circulate and cool the internal air, ensuring that the electronic ballast does not come into contact with external air. Large control boxes will use air conditioning for cooling.

Waterproof grade: IP68 waterproof grade, suitable for occasions with strict requirements.

Installation method: modular combination, open channel installation, lamp tube parallel to water flow direction, easy installation and maintenance.

Application:

Inactivation of viruses, bacteria, spores and pathogens in water.

Treatment of effluent in industry, office, livestock farms, utility, process and aqua culture, etc.

Min ICP 2022003414-1

Min ICP 2022003414-1